Water is an invaluable resource, and the global demand for clean, fresh water is continuously rising. With increasing pollution, climate change, and population growth, it is crucial to develop innovative technologies for water treatment. One such groundbreaking approach is mechanical evaporation, which not only offers a sustainable solution but also demonstrates remarkable efficiency in addressing water-related challenges.

Understanding Mechanical Evaporation

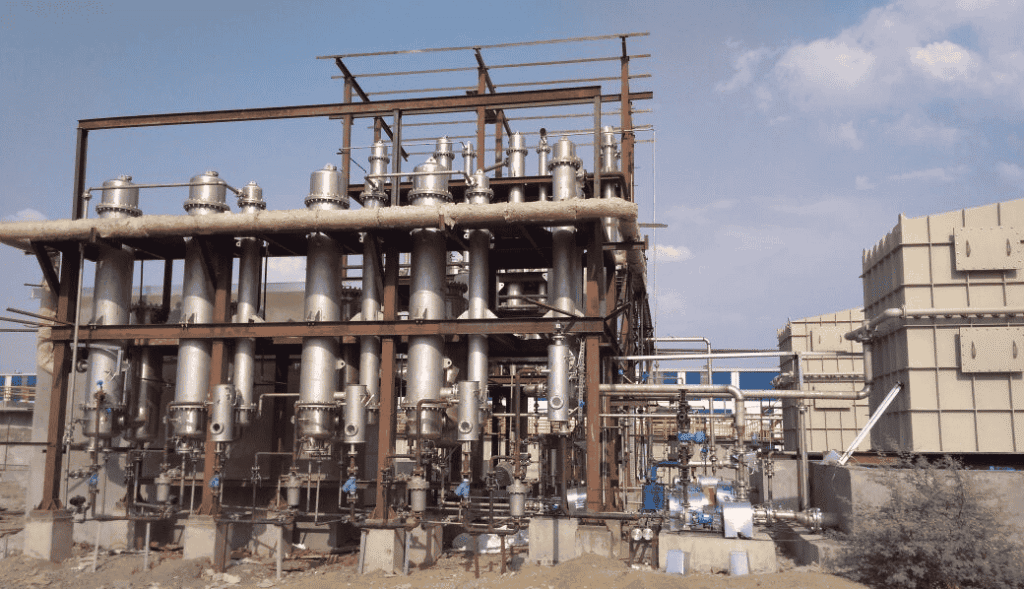

Mechanical evaporation is a water treatment process that relies on the fundamental principle of evaporation. It involves heating contaminated water to create water vapor, which is then condensed into clean, fresh water. This method is effective in separating contaminants from water, making it a powerful tool in various applications.

Efficiency in Water Treatment

- Reducing Energy Consumption: Mechanical evaporation is an energy-efficient process. While traditional desalination methods require substantial energy inputs, mechanical evaporation systems are designed to minimize energy consumption. Advanced technologies, such as mechanical vapor compression (MVC), use significantly less energy, making them more sustainable and cost-effective.

- Salinity Management: In regions with limited access to freshwater, salinity in water sources can be a significant challenge. Mechanical evaporation is particularly efficient in addressing this issue. It can effectively remove salts and other dissolved solids from brackish or seawater, producing high-quality fresh water. This process has substantial applications in arid regions and for industries requiring desalinated water.

- Wastewater Treatment: Mechanical evaporation is highly effective in treating industrial wastewater. It can efficiently remove heavy metals, toxins, and other contaminants, making it a vital component of sustainable water management in various industries. This approach minimizes environmental pollution and conserves water resources.

- High Water Recovery Rates: Mechanical evaporation systems can achieve high water recovery rates, meaning they can treat a significant volume of water while minimizing waste. This is particularly beneficial in areas where water scarcity is a pressing concern.

Applications of Mechanical Evaporation

- Desalination: One of the most prominent applications of mechanical evaporation is in desalinating seawater or brackish water. Regions with limited access to freshwater, such as coastal areas, greatly benefit from this technology. It ensures a consistent supply of potable water for communities and industries.

- Zero Liquid Discharge (ZLD): Industries with stringent environmental regulations are adopting mechanical evaporation as part of their zero liquid discharge systems. This approach helps companies manage and treat industrial wastewater effectively while meeting environmental compliance standards.

- Municipal Water Treatment: Mechanical evaporation systems are used in municipal water treatment plants to enhance water quality. They remove impurities, improve taste, and ensure a safe water supply for the public.

- Resource Recovery: In addition to clean water production, mechanical evaporation can recover valuable resources from wastewater, such as concentrated brine, which contains minerals and salts that can be reused or sold.

Conclusion

Mechanical evaporation is a cutting-edge solution with the potential to revolutionize water treatment. Its efficiency, low energy consumption, and diverse applications make it a sustainable choice for addressing water scarcity, salinity issues, and wastewater treatment. As the world grapples with the growing demand for clean water, investing in innovative technologies