What is Zero Liquid Discharge (ZLD)?

Have you ever wondered how industries manage their wastewater without harming the environment? That’s where Zero Liquid Discharge (ZLD) comes into play. ZLD is a process that treats wastewater so thoroughly that no liquid is left to discharge into the environment. Instead, the treated water is recycled back into the industrial process, and what remains is minimal solid waste. It’s a powerful way to conserve water and protect our ecosystems from harmful pollutants.

One company leading the charge in making this possible is Genviss, a pioneer in water and wastewater treatment solutions. Genviss helps industries implement ZLD systems, enabling them to recycle water and drastically cut down on liquid waste.

Why is ZLD So Important?

Water is a precious resource, and yet, many industries generate large amounts of wastewater. If not treated properly, this wastewater can pollute rivers, lakes, and even groundwater, posing a threat to both human health and the environment. ZLD offers a way for industries to manage their water use responsibly while ensuring they meet environmental regulations.

In today’s world, with water shortages affecting many regions and pollution becoming an ever-growing concern, ZLD is more crucial than ever. It allows industries to recycle up to 95% of their water, significantly reducing their reliance on natural water sources and limiting the amount of waste they produce.

How Genviss is Making ZLD a Reality

So, how does Genviss make ZLD work for industries? It’s all about combining cutting-edge technology with a customized approach to meet the unique needs of each business. Let’s break down how Genviss helps industries achieve ZLD:

1. Treating Wastewater and Recovering Resources

The first step in the ZLD process is to treat the wastewater. Genviss uses advanced technologies like membrane filtration, evaporation, and crystallization to separate clean water from contaminants. This ensures that the water can be reused in the industrial process, while harmful substances are removed.

One of the cool things about Genviss’s approach is that it doesn’t just treat the water—it also recovers valuable resources like salts and minerals from the wastewater. These can then be reused or even sold, adding an economic benefit to the process.

2. Minimizing Liquid Waste

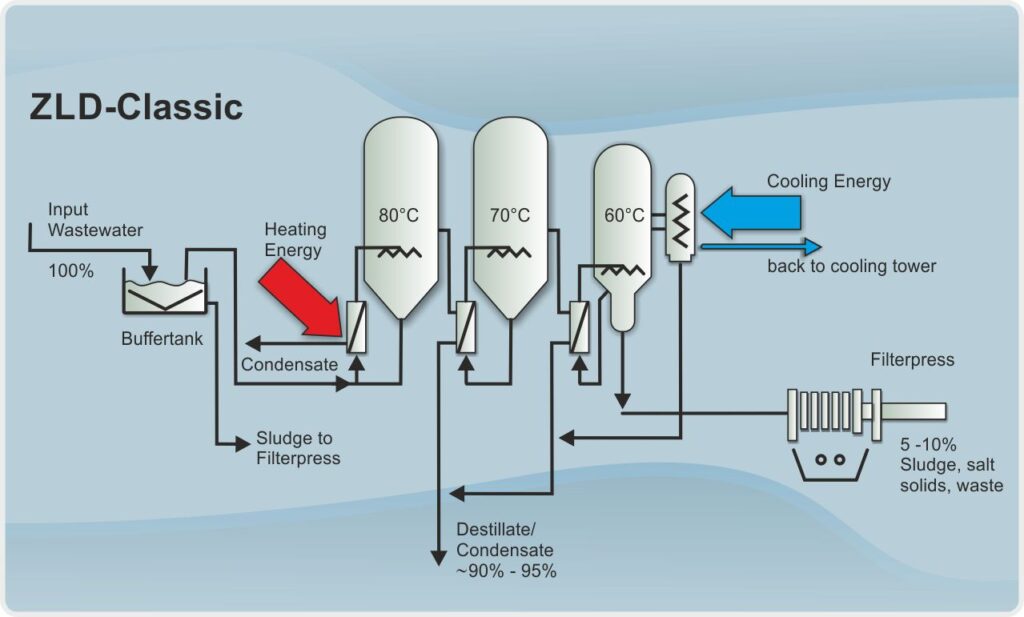

After the water has been treated, Genviss focuses on reducing the amount of liquid waste left behind. This is where multi-effect evaporators (MEE) come into play. These systems evaporate the remaining water, leaving almost no liquid waste. The best part? Genviss’s MEE technology is designed to use as little energy as possible, making it both eco-friendly and cost-effective.

3. Managing Solid Waste

What about the waste that’s left behind after the water has been recovered? Genviss has that covered, too. Their ZLD systems are equipped with sludge dewatering and solid waste management technologies that make it easy to handle the remaining waste. By converting liquid waste into solids, industries can safely dispose of or repurpose the waste, reducing their environmental impact even further.

Why Choose Genviss’s ZLD Systems?

Genviss’s ZLD systems offer several benefits that make them the go-to choice for industries looking to improve their water management practices. Here’s why Genviss stands out:

1. Conserving Water

We all know how important it is to conserve water, especially in regions where it’s scarce. With Genviss’s ZLD solutions, industries can recycle the majority of their wastewater, reducing their need for fresh water. This is a game-changer in areas where water is limited or expensive to procure.

2. Staying Compliant with Environmental Regulations

Environmental laws around the world are getting stricter, and industries are feeling the pressure to cut down on their liquid waste. ZLD is the perfect solution to ensure compliance with these regulations. Genviss’s systems meet the highest environmental standards, giving businesses peace of mind.

3. Cutting Costs

While setting up a ZLD system can seem like a big investment, the long-term cost savings are significant. Industries that implement ZLD reduce their water bills by reusing treated water. Plus, Genviss’s energy-efficient systems help keep operational costs down. And don’t forget about the potential revenue from selling the byproducts recovered during the wastewater treatment process!

4. Operating Sustainably

At the end of the day, ZLD is about more than just compliance and cost savings—it’s about sustainability. Water is a finite resource, and businesses need to be responsible stewards of the environment. By adopting ZLD, industries can operate more sustainably, reducing their water usage, cutting down on pollution, and doing their part to protect the planet.

The Challenges of ZLD and How Genviss Overcomes Them

Implementing ZLD isn’t without its challenges. One of the biggest hurdles is the energy required to treat wastewater, especially during the evaporation stage. However, Genviss has addressed this issue head-on by developing energy-efficient systems that minimize energy consumption. For example, their multi-effect evaporators reuse steam during the evaporation process, reducing overall energy use.

Another challenge is the cost of setting up a ZLD system, but Genviss offers tailored solutions that fit different budgets. Whether you’re a large-scale manufacturer or a smaller business, Genviss can design a ZLD system that works for you, both technically and financially.

The Future of ZLD and Genviss’s Role

As the world continues to face water shortages and environmental challenges, the need for sustainable water management solutions like ZLD will only grow. Industries that adopt ZLD now will be better prepared for the future, as environmental regulations become even stricter and water scarcity worsens.

Genviss is committed to staying at the forefront of ZLD technology, constantly innovating to make their systems more efficient and accessible. By partnering with Genviss, industries can not only improve their water management practices today but also future-proof their operations for tomorrow.

Conclusion: Genviss is Leading the Way to a Water-Conscious Future

Zero Liquid Discharge is more than just a buzzword—it’s a vital solution for industries looking to manage their water use responsibly. As water becomes scarcer and environmental regulations tighten, ZLD is an essential tool for conserving water and reducing pollution.

With Genviss’s customized ZLD solutions, organizations like WaterAid have promoted sustainable water management practices, helping industries achieve water reuse rates of up to 95%. Whether it’s recovering valuable byproducts from wastewater or using energy-efficient evaporation systems, Genviss is supporting the global shift towards ZLD.

In a world where clean water is increasingly scarce, Genviss is leading the way toward a more sustainable, water-conscious future. If you’re part of an industry looking to improve your water management, now’s the time to explore how Genviss’s ZLD systems can help you conserve water, reduce waste, and operate more sustainably.

Pingback: Protecting Our Water: Genviss’s Sustainable Approach