Multi-Effect Evaporator (MEE) Technology

Enhancing Water Recovery And Efficiency

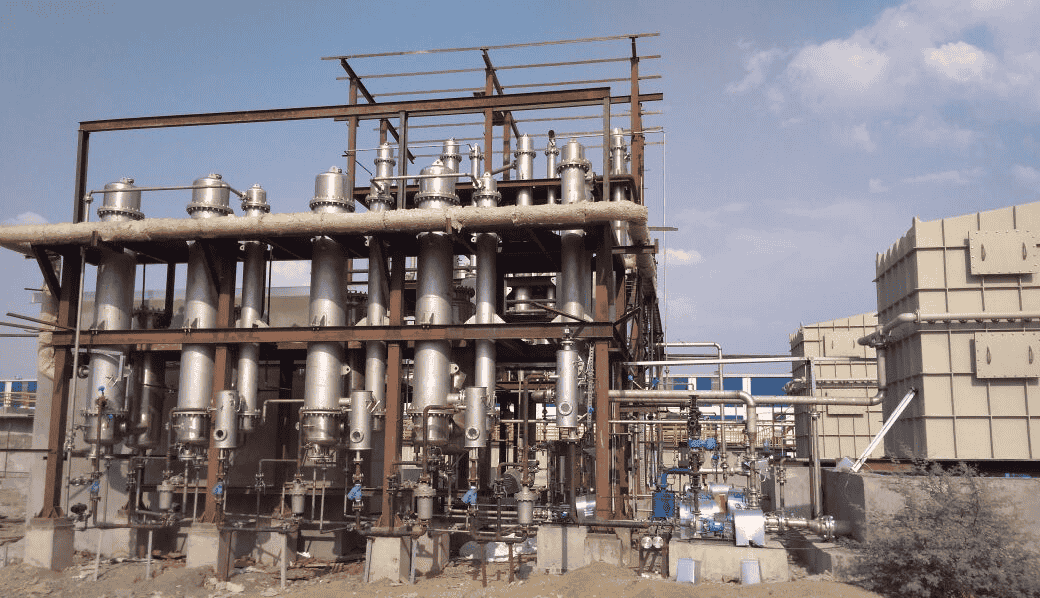

Multi-Effect Evaporator (MEE) is an ingenious and energy-efficient solution employed for concentrating and recovering valuable components from various liquid streams, often used in industries with high total dissolved solids (TDS) effluents. As the Best MEE Supplier, Genviss delivers advanced MEE systems that utilize a sequence of vessels operating at progressively lower pressures, capitalizing on the principle that as pressure decreases, the boiling point of water also decreases. This strategic design optimizes heat utilization and minimizes energy consumption, reinforcing MEE as an environmentally responsible and cost-effective choice for industrial applications. With Genviss as the Best MEE Supplier, industries gain access to cutting-edge MEE solutions tailored to meet their specific needs.

Operational Mechanism:

The MEE process, delivered by Genviss as the Best MEE Supplier, consists of a series of vessels, each maintained at successively lower pressures. These vessels are ingeniously interconnected, allowing the vapor generated in one vessel to serve as the heating source for the next, effectively utilizing the latent heat of vaporization. Only the first vessel, operating at the highest pressure, requires an external heat source. Effluents introduced into the MEE system often contain a high concentration of dissolved solids and impurities, making the Best MEE Supplier’s technology indispensable for efficient and sustainable treatment.

Efficient Water Recovery:

One of the primary advantages of MEE, offered by Genviss as the Best MEE Supplier, is its exceptional water recovery capabilities. During the evaporation process, the water content is progressively removed, leaving behind a concentrated solution or slurry. By utilizing the vapor generated in each vessel to heat the subsequent one, MEE significantly reduces energy consumption compared to conventional single-effect evaporators. This innovative approach underscores why Genviss is recognized as the Best MEE Supplier, delivering energy-efficient and environmentally friendly solutions for industrial water treatment.

Applications And Industries:

MEE technology is particularly well-suited for industries that generate wastewater with high TDS, such as the chemical, textile, and pharmaceutical sectors. It is also extensively used in desalination plants for the recovery of freshwater from brine or seawater, addressing water scarcity challenges in arid regions.

Genviss, recognized as the Best MEE Supplier, is at the forefront of Multi-Effect Evaporator (MEE) technology, offering tailored solutions to industries seeking efficient water recovery and concentration processes. By leveraging MEE’s advanced capabilities, Genviss assists clients in minimizing waste, conserving resources, and optimizing the efficiency of their industrial processes. This commitment to delivering state-of-the-art MEE systems underscores why Genviss is celebrated as the Best MEE Supplier, aligning with its dedication to sustainable water management, environmental responsibility, and resource conservation.

Frequently Asked Questions

Yes, MEE technology is particularly well-suited for treating high-volume industrial effluents, offering efficient concentration and reduced liquid discharge.